Did you know NEFF Automation has a group dedicated to the design, assembly, and support of structural projects? NEFF's Structural Products Group (SPG) includes two SPG Sales Specialists, seven CAD Designers, and over ten Value-Add Technicians. This blog will walk you through how to start your structural project with Structural Products Group and add value to your operations.

Structural Projects

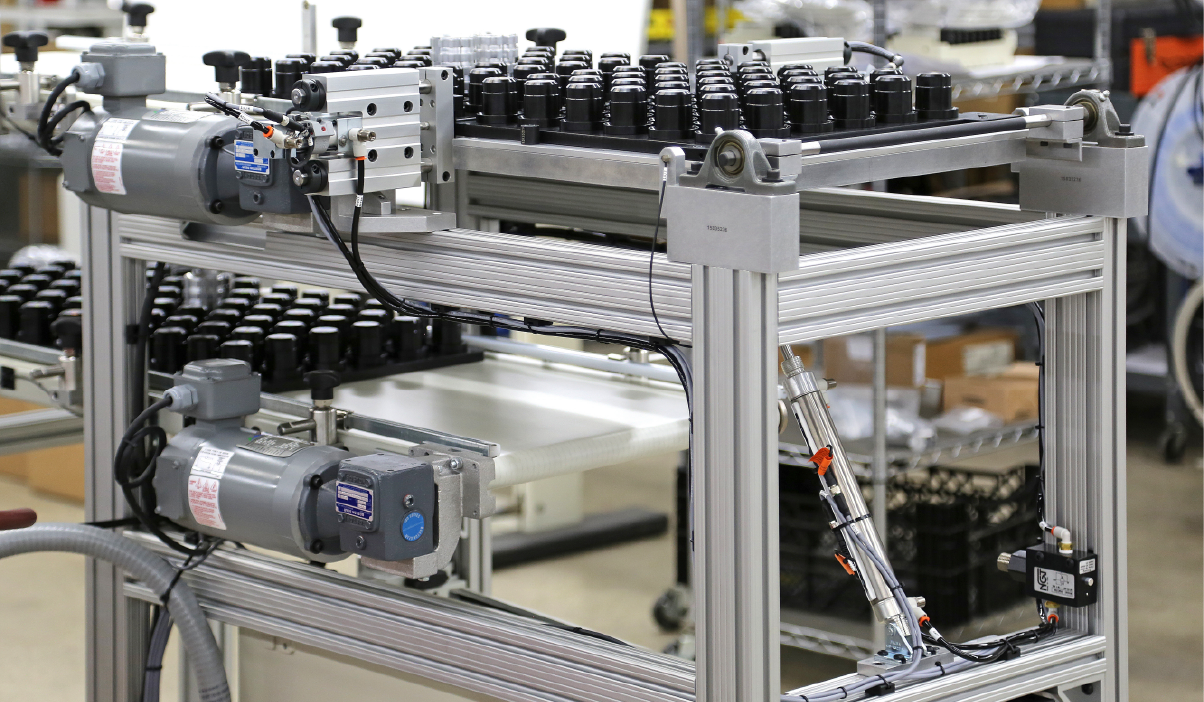

Before we breakdown the process of working with us, let's dive into common projects and applications for our Structural Products Group. NEFF's SPG builds all of its projects with 80/20, Swivellink, and SATech to ensure the highest level of quality and safety.

- Automation: 80/20 t-slotted aluminum profiles are a perfect fit for a wide variety of automated applications like electromechanical systems, machine frames and guarding, conveyor systems, pneumatic systems, mobile workstations, enclosures, and more.

- Ergonomics: Ergonomic workspaces can reduce workplace injury and improve productivity. Workstations, material handling carts, and other framing solutions like articulating arms provide proven results for improving productivity and decreasing turnover.

- Robotics: Whether you need to guard your robotic arms with machine guarding or enclosures, or need a custom configurations to fit your specific application, NEFF has you covered. NEFF specializes in custom structural solutions for robotic applications with multiple peripherals and subsystems.

How Our Process Works

NEFF's Structural Products Group offers full design, assembly, and support services for your project. Here's how it works:

- Consultation: Once you get in touch with your NEFF Structural Products Specialist, they will want to learn more about your project and application to best appropriately guide the CAD Designer.

- Design: Customers work hand-in-hand with NEFF CAD Designers and Structural Products Specialists to make sure their vision becomes a reality.

- Assembly: Once the customer approves the design, this order is sent to our Value-Add Technicians who begin gathering the necessary parts. NEFF gives customers different options for the assembly process - the project can be shipped as kits for the end user to assemble, or a Value-Add Technician can preassemble the build, saving valuable production time. No matter what option the customer chooses, each project is composed of the highest quality structural frames, hardware, and accessories.

- Delivery: Now that the project is built or kitted and packaged, it will be delivered to the customers location.

- Support: Even after assembly and delivery, NEFF provides support for its custom assembled products to ensure each customer is satisfied with their build.

How Do I Get Started?

Just reach out to your local NEFF Sales Representative or contact us here to get your structural project built with confidence.