Automation can be achieved across many tasks, projects, and applications that are proving challenging for your organization to accomplish, staff, or remain competitive in. Exploring automation is exploring your options, and we've made an overview of the best-selling cobot worldwide by Universal Robots. Offered in small, medium, and large payload sizes, the opportunity to implement increased efficiency, production quality, and output can be realized with collaborative robots. Outcomes we see as a result of integrating cobots into production include:

- Increase productivity

- Adapt to changing product demand

- Improve employee well-being and retention

- Staff through labor shortages

What are Cobots?

Cobots are not robots- not exactly. A cobot is a robotic arm, that is designed, programmed, and extensively tested to work safely alongside and with people, often in manufacturing environments and tasks that can be dangerous, tiring, or difficult to repetitively perform. A cobot is a tool that allows for better productivity, increased safety, and more fulfilling opportunities for folks working in production environments. Universal Robots offer ease-of-use, ease of integration, are affordabe, and safe.

Why use Cobots?

Cobots are a valuable part of any operations business plans for future growth, productivity, and longevity. We call it future-proofing. Collaborative robots allow production needs to dictate where cobots are stationed, even switching between applications or adapting to demand, on demand. Cobots allow for the most valuable assets-the workforce-to be protected and upskilled. Cobots are designed to do those tasks that are hard to do day in-and-out, and are often dull, dirty, and dangerous. Cobots also are operable on normal 110v, which is significantly less than traditional robots (the ones you see enclosed in cages) and can often optimize processes to reduce production waste.

What Applications are good for Cobots?

Achievable automation applications can be realized at most manufacturing levels. Cobots and the myriad end effectors and specialty modifications are flexible and deployable across industries and tasks that need increased production and greater through-put. Common projects include:

- palletizing

- welding

- assembly

- machine tending

- material handling & removal

- finishing

- quality inspection

- dispensing

UR Overview & lineup

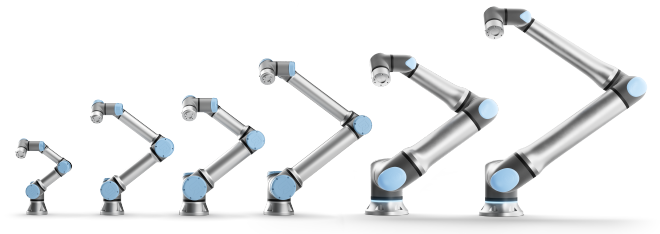

UR Cobots are available in 3 payload classes: small, medium, and large. Versatile, easy to use, and configurable to the task you need a hand with. We often look at projects and tasks that are dirty, dangerous, repetitive, and difficult to staff as good opportunities to introduce cobots into an operation as a game changing tool for productivity and reliability.

Check out this awesome overview

Are Cobots Safe?

You can be confident in the safety of UR cobots to work safely, and to safely work alongside and with your workforce. All models are third-party certified, and go through extensive testing. All UR Cobots comply with Global Standards ISO Standards

a) Safety-rated monitored stop

b) Hand guiding

c) Speed and separation monitoring

d) Power and force limiting

What kind of software is used to program the UR Cobot?

PolyScope has been the leading cobot software since collaborative robots were invented. It was developed alongside UR's first cobot to enable users to program their cobots to perform the tasks they want. Today, there are two different versions of PolyScope for different needs. PolyScope 5 allows experts unlimited possibilities to automate, and PolyScope X includes templatization and makes it easier for operators.

Polyscope is a C++/Python viewer and user interface for 3D data such as meshes and point clouds. It allows you to register your data and quickly generate informative and beautiful visualizations, either programmatically or via a dynamic GUI. The overall objective of Polyscope is to offer a useful visual interface to your data via a single line of code.

By using a URCaps plugin with Polyscope, you have the possibility to extend this functionality, by adding your custom installation screens and program nodes.

What resources are available to me?

To ensure you’re experiencing smooth deployments, continuous production runs, and the greatest ROI, UR offers training and support.

- UR+ Ecosystem: End effectors, seventh axis' and more: UR+

- Academy: UR offers easy and intuitive free e-Learning courses. e-Learning

- As a Certified Partner, NEFF offers engaging in-person training courses: NEFF UR Training

- Community: Online Forum

- My UR Customer Portal: all customer information, software updates, cobot data Customer Portal

We encourage you to connect with your area resources that are invested in your success. NEFF has been an automation and reliability resource for manufacturers and machine shops for almost 100 years, and our dedicated teams are devoted to your successful automation journey. We support manufacturing by providing you with the solutions, technology, and information that allows you to confidently make the decisions that protect and enhance your assets and bottom line.