Home / Services

Services

Custom automation solutions, value-add services, and industrial products for virtually any application.

Anyone Can Sell Parts. NEFF Provides Solutions.

NEFF's different departments work cohesively to provide highly specialized and expertly engineered solutions based on our customers' specific applications. Our dedicated Customer Service department and Sales team form lasting relationships with our customers to identify the right industrial parts and solutions for their specific needs and industry.

NEFF Automation's Value-Add department kits and builds structural projects out of rigid aluminum framing. Value-Add also creates custom pneumatic sub-assemblies that go through a meticulous testing process to guarantee quality and reliability.

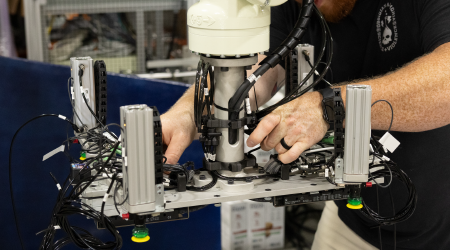

Finally, NEFF's Automated Solutions Group (ASG) fully designs, builds, and ships custom light automation solutions like robotic cells, quality inspection machines, motion control systems, packaging solutions, custom workstations, end-of-arm tooling, and much more.

Our Services

Check out the many different solutions NEFF provides.

Custom Automation Solutions

Comprised of a experienced team of engineers, designers, and programmers, NEFF's ASG department works cohesively with our customers in designing, building, and shipping custom automated solutions. ASG creates unique solutions for manufacturers of all sizes that are specifically designed to optimize their production processes and improve their competitiveness.

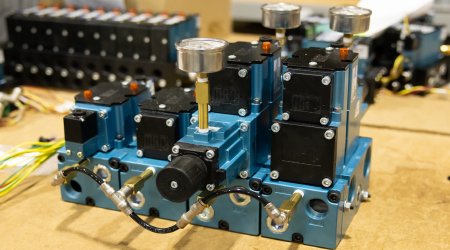

Pneumatic Assembly

NEFF's Value-Add teams assemble pneumatic components with top quality valves and manifolds into complete sub-assemblies based on application requirements. Every valve stack is rigorously tested to ensure quality and fast installation. Along with NEFF's industry-leading service, MAC Valves provide highly engineered pneumatic technology designed for harsh environments.

Structural Assembly

The backbone of any system, quality structural assemblies are critical for machine reliability and workplace safety. Have us kit together your next build (like workstations, machine frames, machine guarding, etc.) with instructions for assembly or save valuable production time by having our seasoned Value-Add team pre-assemble your project with 80/20 aluminum extrusion.

Industrial Products

Along with creating automation solutions, NEFF offers distribution services by selling, packaging, and shipping industrial products for over 50 leading high-tech manufacturers. Order components like valves, cordsets, sensors, suction cups, cylinders, extrusion, and more by contacting your local NEFF customer service department or submitting a quote request.

Universal Robots Certified Training Courses

NEFF Automation provides certified Universal Robots training courses at our Indianapolis, Cleveland, and Grand Rapids branches. Hosted by experienced industrial robotics specialists, these courses offer two full days of hands-on experience with cobots to teach you how to seamlessly implement your UR cobot into production.

Register for a UR Training Near You

Start Building Your Custom Project Today

NEFF's Automated Solutions Group specializes in taking your process improvement idea and turning it into a reality. Reach out to NEFF to see if we would be a good fit for your automation project.