Industrial automation is evolving fast, but many factories are still trying to make 3-D decisions with 2-D tools. If you’ve ever tried to determine part height, orientation, or seating using a traditional photoelectric sensor or a 2-D camera, you already know the limitations. Lighting changes, surface color variations, reflections, and shadows all introduce uncertainty. That’s where true 3-D sensing changes the game.

In this blog, we break down one of the most exciting sensing technologies hitting the industrial automation space today: the Pepperl+Fuchs SmartRunner 3-D. We’ll go deeper into why this technology matters, where it fits, and how it bridges a critical gap between basic sensors and complex machine vision systems.

The Problem With Making 3-D Decisions Using 2-D Sensors

Let’s start with the reality on most factory floors: traditional sensors can tell you if something is present, 2-D vision systems can tell you what something looks like, but neither can reliably tell you:

-

How tall an object is

-

Whether a part is fully seated

-

The exact position and orientation in space

-

If a shape or contour is correct

Depth, the most critical piece of information, is missing.

Many automation challenges don’t fail because sensors are “bad.” They fail because the wrong type of sensing is being used for the job.

Where SmartRunner 3-D Fits

The SmartRunner 3-D sits in a unique sweet spot in the market. It’s more powerful and reliable than 2-D sensors, smaller and easier to integrate than full-scale 3-D machine vision systems, and more affordable and practical than legacy 3D solutions. Most importantly, it provides true 3-D data in the form of a point cloud. Not a guess, not an inference, but actual spatial measurements.

Why a True 3-D Point Cloud Changes Everything

Unlike laser scanners or safety sensors that give you limited profiles or zones, SmartRunner 3-D outputs a real 3-D point cloud. This opens the door to a wide range of industrial applications, including:

-

Robotics and pick-and-place

-

Bin picking

-

Packaging verification

-

Assembly validation

-

Quality inspection

-

Presence and completeness checks

Because you’re working with depth, shape, and contour information, the system is far less affected by lighting inconsistencies, color variations, and surface texture changes.

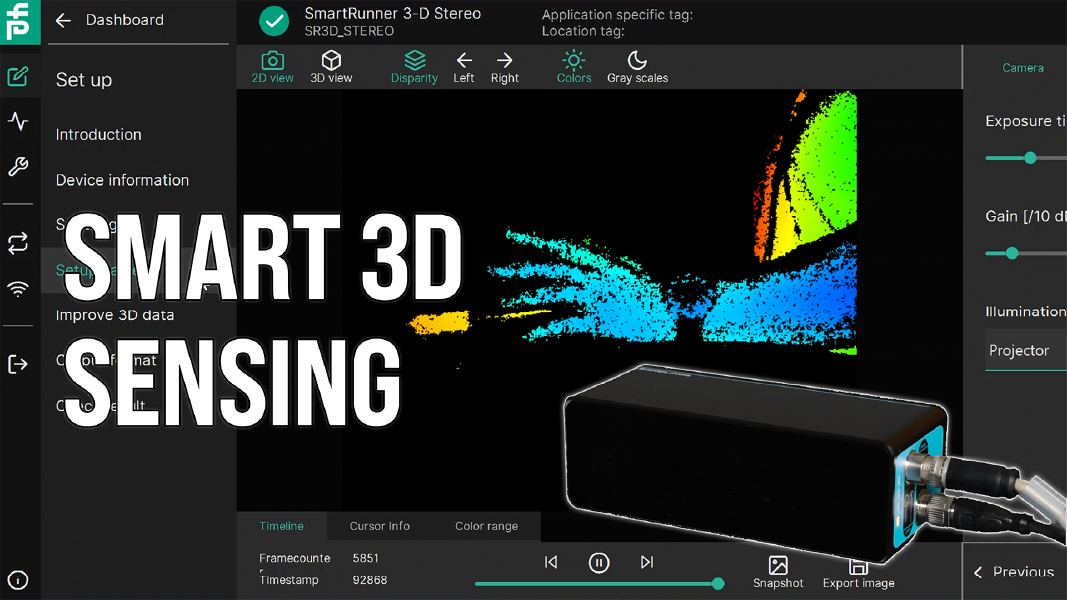

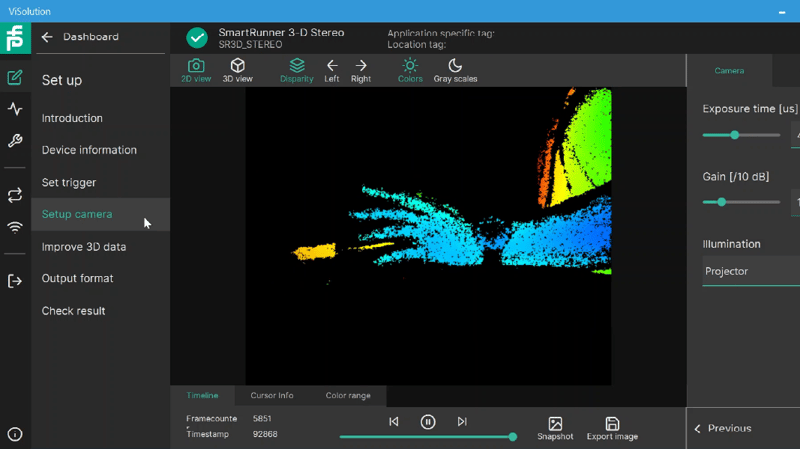

Visualizing Depth in Real Time

A standout moment in the walk-through video below is the live visualization of depth data. Instead of a flat image, operators see:

-

Color-coded depth information

-

Clear differentiation between foreground, background, and out-of-range areas

-

A manipulable 3-D view that can be rotated and analyzed

This isn’t just cool, it’s practical. When operators and engineers can see depth, troubleshooting becomes faster, setup becomes easier, and confidence in the system goes way up.

If your application requires reliable spatial understanding, accurate depth measurements, and robust performance in industrial environments, then it’s time to stop forcing 2-D solutions to solve 3-D problems.

The Pepperl+Fuchs SmartRunner 3-D doesn’t replace every vision system, but it fills a critical gap that many factories didn’t even realize they had. Check out our video below for a full walkthrough or request a product demo from our team of automation experts.