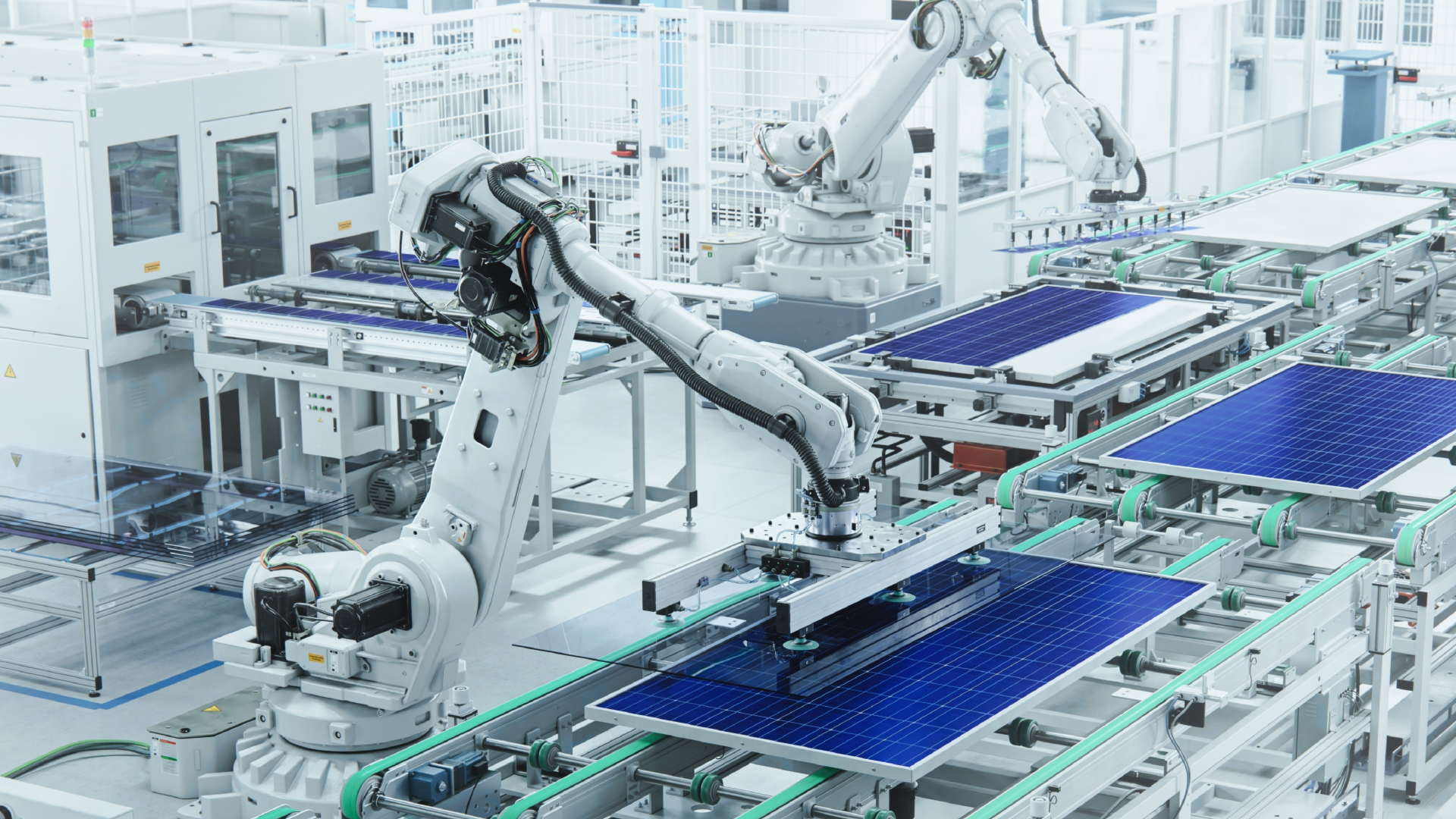

The SMART Factory. It’s more than a few buzzwords and a sensor-connected app connected to the factory floor to track your production. The SMART factory of today is deliberate and precise, charting out a road map of growth opportunities, where inefficiencies can be curtailed, along with where to pursue the right path of automation. The modern factory is no longer asking “why automate” but “when and how”.

Specific Goals

Pursuing a thoughtful path to successful automation is a journey that should be taken on with specific outcomes in mind. Allow the focus of this automation journey to be productivity. Decision makers across industries, from engineering to maintenance, production and the board, all seek enhanced productivity. As the major driver of industrial growth and industry, productivity is important to understand as an area of investment that has the potential for high return, especially against high-cost supply chain components in changing economic conditions. Focusing on increasing productivity by automation positions our Smart Factory journey to a specific path forward.

Measuring Productivity

How do we measure productivity in automation and smart factories? Embrace solutions that enable a defined, purposeful strategy that encourages current resources - like your workforce - to shift from traditional manual production roles into new deployments that allow for upskilling, new training, and innovation. Investment in human capital and innovation is critical to level up automation for a Smart Factory. We can invest in innovation by embracing disruptive ideas, reading up on industry research, and expanding our knowledge base through scientific studies, white papers, and networking with peers that have previous experience. We can invest in proven technologies, like smart sensing solutions or robotic work cells that help us measure productivity from a skills perspective, and still enhance our production output.

Achievable Productivity

Achievable productivity can start with the simplest of goals. Perhaps utilities are eating away at your bottom line, and inflation isn’t helping you control costs. How can we reduce energy consumption and increase efficiency of internal services? Easy answers like reliable pneumatics, appropriate fittings, and knowledgeable staff are a crucial. We can certainly start adding sophisticated Industry 4.0 solutions that permit increased output by using collaborative robots that flex with changing production. We can procure a cost-benefit study of integrating sensors into machine panels that monitor safety and data, while providing intelligent preventative maintenance scheduling from industry experts are another way to look at achievable productivity progress.

Realistic Outcomes

According to the 2022 NIST’s Manufacturing Cost Guide:

“Discrete technology manufacturing (computer manufacturing, transportation equipment manufacturing, machinery manufacturing, and electronics manufacturing) accounts for 31 % of all manufacturing equipment in the United States…downtime amounts to 8.3 % of planned production time and amounts to $245 billion for discrete … In addition to downtime, defects result in additional losses. The Manufacturing Cost Guide estimates that defects amount to between $32.0 billion and $58.6 billion for discrete manufacturing.”

The ability to reliably move forward in the Smart Factory is to reduce downtime and defects. Precise automation initiatives increases quality and capacity, while improving product function by mitigating errors and defects. Reliability is the outcome of careful planning and programming.

Timely Automation for today and tomorrow

A timely outcome to finally consider when pursuing automation is the ability to provide for the needs of production today, and to be ready for the challenges of tomorrow. Consider that an immediate outcome of increasing productivity by automation is yielding better quantity outputs, while a long-term goal of working to implement the Smart Factory would be the ability to produce the same quality goods while using less material. The effect this could have on supply chain eventually could be staggering, with reductions in the burden activities of transportation, material handling, machinery, inventory costs, and energy use.

Our workforce today, impacted by technological, social, environmental, and career changes, are more likely than ever to simultaneously keep up to date with technology, while not considering skilled trades or traditional factory employment. By investing in innovative technology solutions, and uplifting the most valuable resource of all- our human capital, the Smart Factory can address the issues of today and tomorrows production, and enable a workforce that is engaged and committed to manufacturing success. The true Smart Factory enables both productivity for both profitable output and positive outcomes for the workforce.

We encourage you to connect with your area resources that are invested in your success. NEFF has been an automation and reliability resource for manufacturers and machine shops for almost 100 years, and our dedicated teams are devoted to your successful automation journey. We support manufacturing by providing you with the solutions, technology, and information that allows you to confidently make the decisions that protect and enhance your assets and bottom line.