Home / Industries / Automotive

Automotive Industry

From start to finish, NEFF optimizes automotive manufacturing processes.

In the fast-paced automotive industry, turnover and supply chain disruptions can quickly decrease production volume. Other common issues like changing regulatory requirements and customer preference creates a moving target for automotive manufacturers to meet.

NEFF supports Tier 1, 2, and 3 automotive suppliers that specialize in every stage of production, from body manufacturing and engine assembly to final assembly and quality control. We work directly with automotive manufacturers to develop unique and compliant solutions that surpass their production goals.

Common Automotive Applications

Check out the common applications that we optimize in the automotive industry.

Assembly

Reduce assembly times, increase production speeds, and improve product quality with collaborative robots. Industrial robots allow you to lower operation costs and offer a fast return on investment.

CNC Machine Tending

Relieve machine operators from physically demanding, repetitive work and eliminate the risk of injuries on the job. A collaborative robot can be used to tend machines such as CNC, injection molding, press brakes, stamping presses, and more.

Welding

Collaborative and traditional robots can handle Arc, TIG, laser, MIG, ultrasonic, plasma, and spot welding, as well as soldering and brazing. Add flexibility, efficiency, and freedom to all of your welding processes while maintaining consistently high weld quality.

Material Handling

Efficiently moving parts is essential for manufacturers. NEFF works closely with our customers to design custom material handling solutions that fit their unique needs, whether they require AMRs, conveyors, or pneumatic systems.

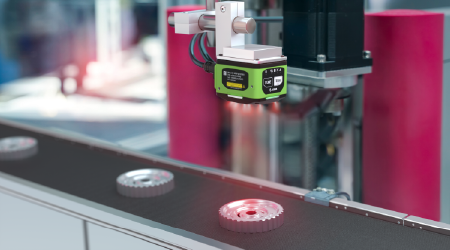

Quality Inspection

Automated 2D/3D part inspection uses data to improve quality control, reducing errors compared to human inspection. Identify flaws in part sizes and surface irregularities with machine vision while ensuring better traceability.

End-of-Line Palletizing

One of the simplest places to start automating, palletizing is dull, strenuous, and dangerous due to its repetitive nature. Improve your throughput and save on injury claims with turnkey robotic palletizing solutions.

Press Brake Tending

Ensure consistent bends in car body parts while reducing labor requirements with automation. Collaborative and industrial robots can tend press brake machines by simply picking, placing, and orienting sheet metal.

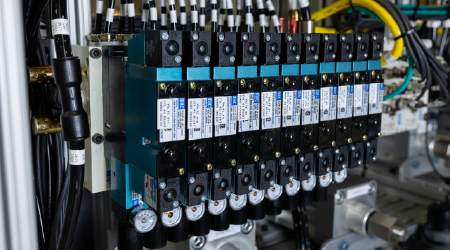

Light Automation

Many small shops are who have yet to adopt automated processes are starting with safety solutions (safety guarding, light curtains, sensors), aluminum extrusion, or pneumatic automation (valves, linear actuators).