Home / Manufacturers / Universal Robots

Universal Robots

Available in all NEFF territories.

Collaborative Robots

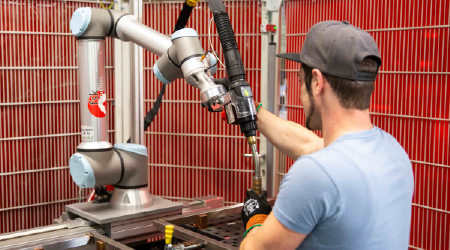

Universal Robots manufactures collaborative robots designed to work hand-in-hand with human labor. Universal Robots are a perfect solution for a wide variety of industrial light to medium duty applications in nearly every industry. All of these benefits have made Universal Robots collaborative robots a game-changer for a wide variety of applications.

NEFF Automation hosts Universal Robots authorized training courses. These two-day training sessions give you hands on experience setting up applications using collaborative robots and popular peripherals. Learn basic and advanced concepts from authorized UR trainers, including how to operate the robot safely, optimizing programs for applications like pick and place, palletizing, and dispensing, and handling peripherals like grippers, conveyors, and sensors.

Common Applications

Universal Robots create flexible automation solutions for varying applications, industries, and production environments.

Palletizing

Relieve workers from repetitive work and heavy lifting by automating your palletization tasks. When paired with Robotiq’s UR+ Certified Palletizing Solution, Universal Robots can easily be deployed with an out-of-the-box hardware and software solution.

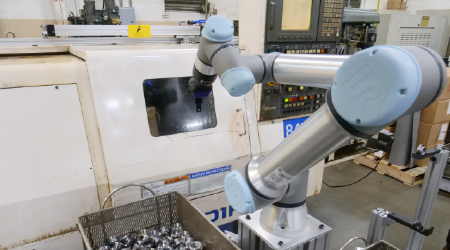

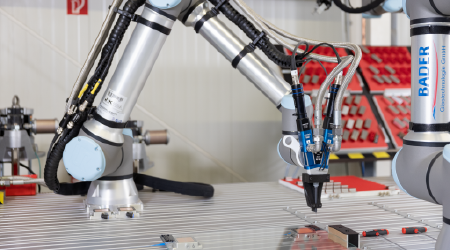

Machine Tending

Relieve machine operators from physically demanding, repetitive work and eliminate the risk of injuries on the job. A collaborative robot can be used to tend machines such as CNC, injection molding, press brakes, stamping presses, and more.

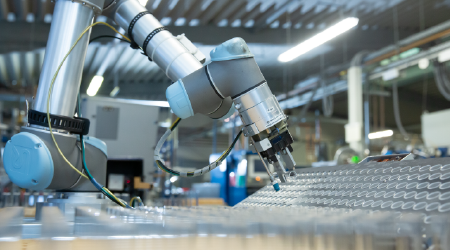

Material Handling

Streamline your material handling, packaging and palletizing, bin picking, labeling and kitting operations with collaborative robots. Cobots with innovative grippers, computer vision, and machine-learning systems can pick up a wide range of objects.

Welding

Collaborative robots can handle Arc, TIG, laser, MIG, ultrasonic, plasma, and spot welding, as well as soldering and brazing. Add flexibility, efficiency, and freedom to all of your welding processes while maintaining consistently high weld quality.

Bin Picking

With powerful, AI-driven vision and path planning software, Universal Robots can pick metal, plastic, clear, or even reflective parts with stunning repeatability. With no custom programming required, random bin picking is possible with cobots.

Quality Inspection

Increase your consistency and maintain high levels of product quality with Universal Robots. UR cobots feature a movement repeatability of up to +/- 0.03 mm (30 microns), enabling to consistently take measurements for quality inspection and testing.

Assembly

Reduce assembly times, increase production speeds, and improve product quality with collaborative robots. Cobots allow you to lower operation costs and offer an average of just 195 day return-on-investment, making it the fastest ROI in the robot industry.

Dispensing

Add flexibility, efficiency, and freedom to your gluing, sealing, painting, and other dispensing applications with collaborative robots. Universal Robots reduce waste and optimize production for any size of operation with their built in force/torque sensing.

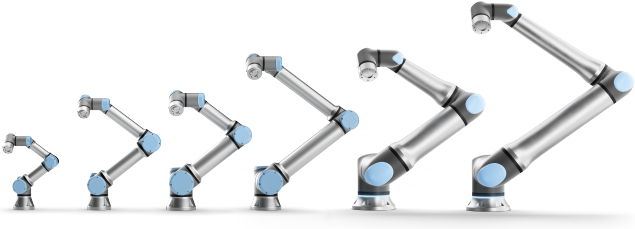

Collaborative Robots

Universal Robots create flexible automation solutions for varying applications, industries, and production environments.

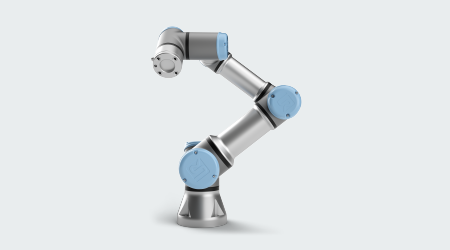

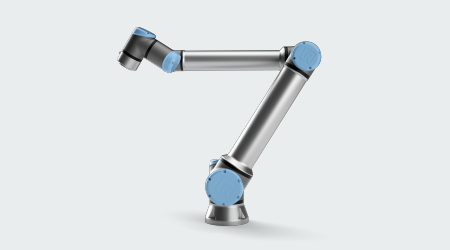

UR3e

Ultra-lightweight and compact cobot

The smallest collaborative robot in UR's lineup, the UR3e is a perfect fit for tight workspaces.

Reach: 500 mm / 19.7 in

Payload: 3 kg / 6.6 lbs

Footprint: Ø 128 mm

Weight: 11.2 kg / 24.7 lbs

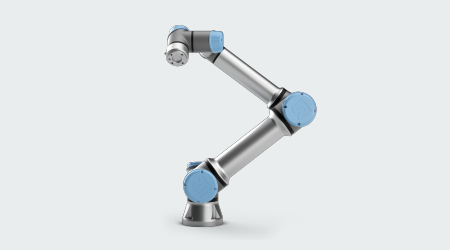

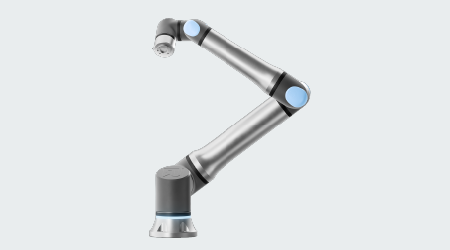

UR7e

Lightweight and versatile cobot

The second smallest UR cobot, the UR7e allows you to perform precise tasks that require a longer reach.

Reach: 850 mm / 33.5 in

Payload: 7.5 kg / 16 lbs

Footprint: Ø 151 mm

Weight: 20.6 kg / 45.4 lbs

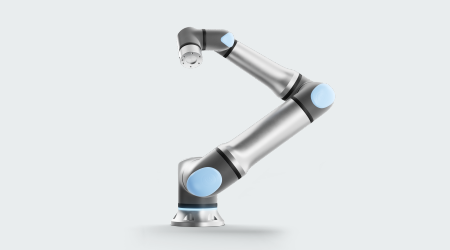

UR12e

Medium-sized and versatile cobot

The most popular Universal Robot, the UR12e tackles medium duty applications seamlessly.

Reach: 1300 mm / 51.2 in

Payload: 12.5 kg / 27.55 lbs

Footprint: Ø 190 mm

Weight: 33.5 kg / 73.9 lbs

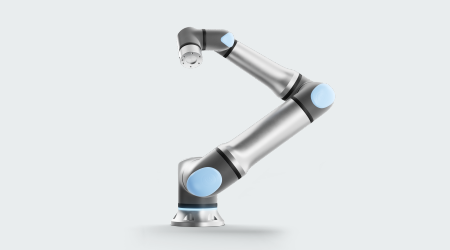

UR15

Outsized speed and performance

The UR15 reaches impressive speeds of up to 5 m/s while completing heavy duty tasks with precision.

Reach: 1300 mm / 51.2 in

Payload: 15 kg / 33.07 lbs

Footprint: Ø 204 mm

Weight: 40.7 kg / 89.7 lbs

UR16e

Heavy duty and compact cobot

The largest payload e-series cobot, the UR16e suits tasks with heavy objects where space is limited.

Reach: 900 mm / 35.4 in

Payload: 16 kg / 35.3 lbs

Footprint: Ø 190 mm

Weight: 33.1 kg / 73 lbs

UR20

Heavy payload and fast cobot

Featuring the longest reach of UR's heavy payload cobots, the UR20 can lift heavy objects over long distances.

Reach: 1750 mm / 68.9 in

Payload: 20 kg / 44.1 lbs

Footprint: Ø 245 mm

Weight: 64 kg / 141.1 lbs

UR30

Heavy payload and compact cobot

The strongest Universal Robot, the all new UR30 handles heavy, high torque applications with ease.

Reach: 1300 mm / 51.2 in

Payload: 30 kg / 66.13 lbs

Footprint: Ø 245 mm

Weight: 63.5 kg / 139.9 lbs

UR30

Heavy payload and compact cobot

The strongest Universal Robot, the all new UR30 handles heavy, high torque applications with ease.

Reach: 1300 mm / 51.2 in

Payload: 35 kg / 77 lbs

Footprint: Ø 245 mm

Weight: 63,5 kg / 139.9 lbs